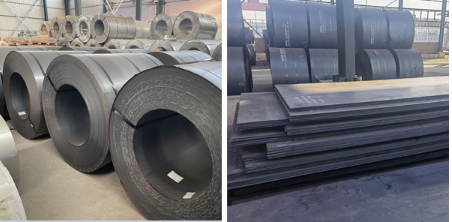

ST37 Carbon steel coil

Product Description

ST37 steel (1.0330 material) is a cold formed European standard cold rolled high-quality low-carbon steel plate. In BS and DIN EN 10130 standards, it includes five other steel types: DC03 (1.0347), DC04 (1.0338), DC05 (1.0312), DC06 (1.0873) and DC07 (1.0898). The surface quality is divided into two types: DC01-A and DC01-B.

DC01-A: Defects that do not affect the formability or surface coating are allowed, such as air holes, slight dents, small marks, slight scratches and slight coloring.

DC01-B: The better surface shall be free of defects that may affect the uniform appearance of high-quality paint or electrolytic coating. The other surface shall meet at least surface quality A.

The main application fields of DC01 materials include: automobile industry, construction industry, electronic equipment and household appliances industry, decorative purposes, canned food, etc.

Product Details

| Product Name | Carbon Steel Coil |

| Thickness | 0.1mm - 16mm |

| Width | 12.7mm - 1500mm |

| Coil Inner | 508mm / 610mm |

| Surface | Black skin, Pickling, Oiling,etc |

| Material | S235JR, S275JR, S355JR, A36, SS400, Q235, Q355, ST37, ST52, SPCC, SPHC, SPHT, DC01, DC03, etc |

| Standard | GB, GOST, ASTM, AISI, JIS, BS, DIN, EN |

| Technology | Hot rolling, Cold rolling, Pickling |

| Application | Widely used in machinery manufacturing, construction, automobile manufacturing and other fields |

| Shipment time | Within 15 - 20 working days after receiving the deposit |

| Export packing | Waterproof paper, and steel strip packed. Standard Export Seaworthy Package.

Suit for all kinds of transport, or as required |

| Minimum Order Quantity | 25Tons |

Main Advantage

Pickling plate is made of high-quality hot-rolled sheet as raw material. After the pickling unit removes the oxide layer, trims and finishes, the surface quality and use requirements (mainly cold-formed or stamping performance) are between hot-rolled and cold-rolled The intermediate product between the plates is an ideal substitute for some hot-rolled plates and cold-rolled plates. Compared with hot-rolled plates, the main advantages of pickled plates are: 1. Good surface quality. Because the hot-rolled pickled plates remove the surface oxide scale, the surface quality of the steel is improved, and it is convenient for welding, oiling and painting. 2. The dimensional accuracy is high. After leveling, the plate shape can be changed to a certain extent, thereby reducing the deviation of unevenness. 3. Improve the surface finish and enhance the appearance effect. 4. It can reduce environmental pollution caused by users' scattered pickling. Compared with cold-rolled sheets, the advantage of pickled sheets is that they can effectively reduce purchase costs while ensuring the surface quality requirements. Many companies have put forward higher and higher requirements for the high performance and low cost of steel. With the continuous advancement of steel rolling technology, the performance of hot-rolled sheet is approaching that of cold-rolled sheet, so that "replacement of cold with heat" is technically realized. It can be said that the pickled plate is a product with a relatively high performance-to-price ratio between the cold-rolled plate and the hot-rolled plate, and has a good market development prospect. However, the use of pickled plates in various industries in my country has just started. The production of professional pickled plates began in September 2001 when Baosteel's pickling production line was put into operation.

Product display

Packing and shipping

We are customer-centric and strive to provide customers with the best quality products and the best prices according to their cutting and rolling requirements. Provide customers with the best services in production, packaging, delivery and quality assurance, and provide customers with one-stop purchasing. Therefore, you can rely on our quality and service.