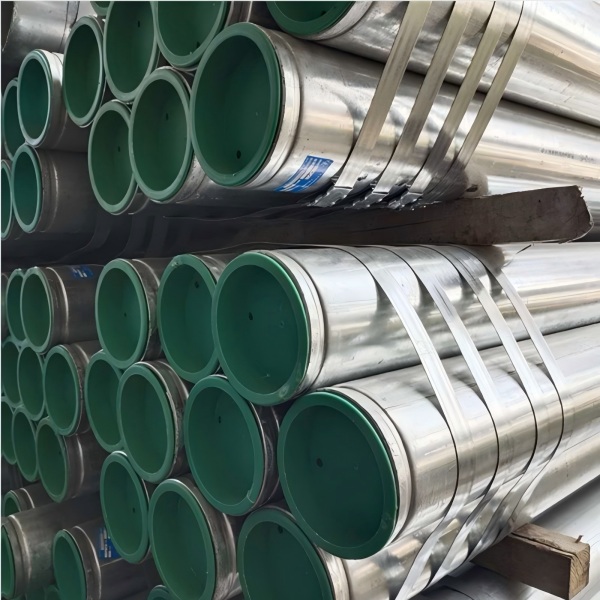

Galvanized Pipe

Products Description

I. Core Classification: Classification by Galvanizing Process

Galvanized pipe is primarily divided into two categories: hot-dip galvanized pipe and cold-dip galvanized pipe. These two types differ significantly in process, performance, and application:

• Hot-dip galvanized pipe (hot-dip galvanized pipe): The entire steel pipe is immersed in molten zinc, forming a uniform, dense zinc layer on the surface. This zinc layer is typically over 85μm thick, boasting strong adhesion and excellent corrosion resistance, with a service life of 20-50 years. It is currently the mainstream type of galvanized pipe and is widely used in water and gas distribution, fire protection, and building structures.

• Cold-dip galvanized pipe (electrogalvanized pipe): The zinc layer is deposited on the steel pipe surface through electrolysis. The zinc layer is thinner (typically 5-30μm), has weaker adhesion, and offers far less corrosion resistance than hot-dip galvanized pipe. Due to its insufficient performance, galvanized pipes are currently prohibited from use in applications requiring high corrosion resistance, such as drinking water pipes. They are only used in limited quantities in non-load-bearing and non-water-related applications, such as decoration and lightweight brackets.

II. Main Advantages

1. Strong Corrosion Resistance: The zinc layer isolates the steel pipe from air and moisture, preventing rust. Hot-dip galvanized pipes, in particular, can withstand long-term use in harsh environments such as humid and outdoor environments.

2. High Strength: Retaining the mechanical properties of carbon steel pipes, they can withstand certain pressures and weights, making them suitable for applications such as structural support and fluid transport.

3. Reasonable Cost: Compared to stainless steel pipes, galvanized pipes have lower production costs. Compared to ordinary carbon steel pipes, while the galvanizing process costs increase, their service life is significantly extended, resulting in a higher overall cost-effectiveness.

III. Main Applications

• Construction Industry: Used in fire protection pipes, water supply and drainage pipes (non-potable water), heating pipes, curtain wall support frames, etc.

• Industrial Sector: Used as fluid transport pipes (such as water, steam, and compressed air) and equipment brackets in factory workshops.

• Agriculture: Used in farmland irrigation pipes, greenhouse support frames, etc.

• Transportation: Used in small quantities as foundation pipes for highway guardrails and streetlight poles (mostly hot-dip galvanized pipes).

Product Display