Stainless Steel Plate

Product description

| Product Name | Stainless Steel Plate/Sheet |

| Standard | ASTM,JIS,DIN,GB,AISI,DIN,EN |

| Material | 201, 202, 301, 301L, 304, 304L, 316, 316L, 321, 310S, 904L, 410, 420J2, 430, 2205, 2507, 321H, 347, 347H, 403, 405, 409, 420, 430, 631, 904L, 305, 301L, 317, 317L, 309, 309S 310 |

| Technique | Cold drawn, Hot rolled, Cold rolled and Others. |

| Width | 6-12mm or Customizable |

| Thickness | 1-120mm or Customizable |

| Length | 1000 - 6000mm or Customizable |

| Surface Treatment | BA/2B/NO.1/NO.3/NO.4/8K/HL/2D/1D |

| Origin | China |

| HS Code | 7211190000 |

| Delivery Time | 7-15 days, depending on the situation and quantity |

| After-sales Service | 24 hours online |

| Production Capacity | 100000 Tons/Year |

| Price Terms | EXW, FOB, CIF, CRF, CNF or Others |

| Loading Port | Any port in China |

| Payment Term | TT, LC,Cash, Paypal, DP, DA,Western Union or Others. |

| Application | 1. Architectural decoration. Such as exterior walls, curtain walls, ceilings, stair handrails, doors and windows, etc. |

| 2. Kitchen furniture. Such as kitchen stove, sink, etc. | |

| 3. Chemical equipment. Such as containers, pipelines, etc. | |

| 4. Food processing. Such as food containers, processing tables, etc. | |

| 5. Automobile manufacturing. Such as vehicle body, exhaust pipe, fuel tank, etc. | |

| 6. Electronic devices. Such as manufacturing casings, structural components, etc. for electronic devices. | |

| 7. Medical equipment. Such as surgical instruments, surgical instruments, medical utensils, etc. | |

| 8. Shipbuilding. Such as ship hulls, pipelines, equipment supports, etc. | |

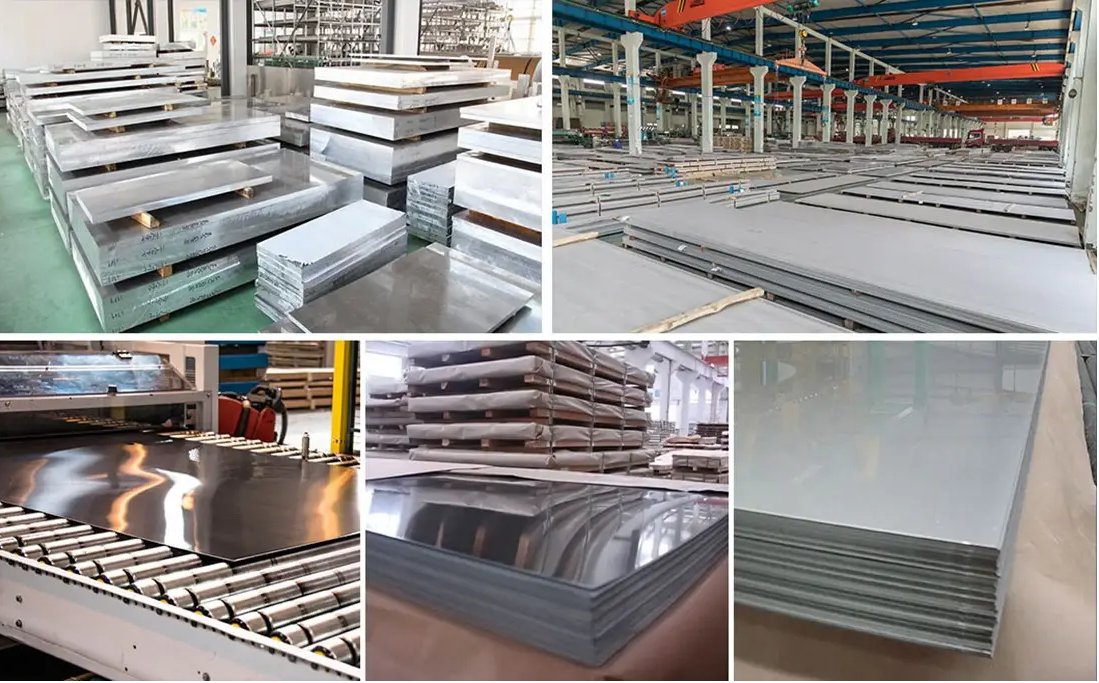

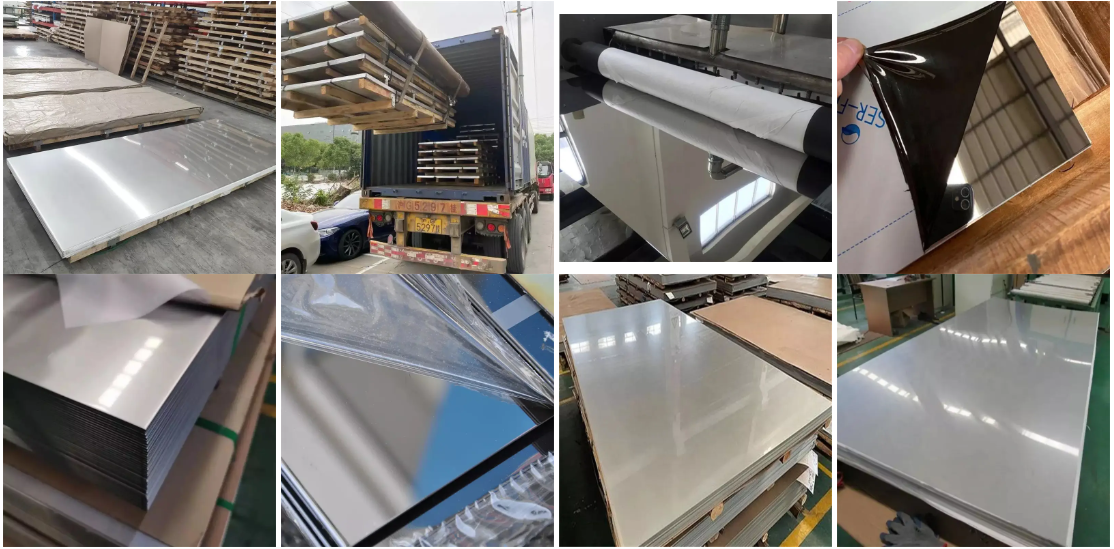

| Packaging | Bundle, PVC Bag, Nylon Belt, Cable Tie, Standard export seaworthy package or as Request. |

| Processing Service | Bending, Welding, Decoiling, Punching, Cutting and Others. |

| Tolerance | ±1% |

| MOQ | 5 tons |

Lead time

| Quantity (tons) | 1 - 50 | 51 - 100 | > 100 |

| Lead time (days) | 7 | 15 | To be negotiated |

Specification

|

Product |

Stainless Steel Sheet, Stainless Steel Plate |

|

Material Type |

Ferrite stainless steel, magnetic; Austenitic stainless steel, Non-magnetic. |

|

Grade |

Mainly201, 202, 304, 304L, 304H, 316, 316L,316Ti,2205, 330, 630, 660, 409L, 321, 310S, 410, 416, 410S, 430, 347H, 2Cr13, 3Cr13 etc |

|

300series:301,302,303,304,304L,309,309s,310,310S,316,316L,316Ti,317L,321,347 |

|

|

200series:201,202,202cu,204 |

|

|

400series:409,409L,410,420,430,431,439,440,441,444 |

|

|

Others:2205,2507,2906,330,660,630,631,17-4ph,17-7ph, S318039 904L,etc |

|

|

Duplex stainless steel:S22053,S25073,S22253,S31803,S32205,S32304 |

|

|

Special Stainless Steel:904L,347/347H,317/317L,316Ti,254Mo |

|

|

Advantage |

We have stock, about 20000 tons. 7-10 days delivery , no more than 20 days for bulk order |

|

Technology |

Cold Rolled/ Hot Rolled |

|

Length |

100~12000 mm/ as request |

|

Width |

100~2000 mm/ as request |

|

Thickness |

Cold Roll:0.1~3 mm/ as request |

|

|

Hot Roll:3~100 mm/ as request |

|

Surface |

BA, 2B, 2D, 4K, 6K, 8K, NO.4, HL, SB, Embossed |

|

Leveling: improve flatness, esp. for items with high flatness request. |

|

|

Skin-Pass: improve flatness, higher brightness |

|

|

Other Choices |

Cutting:Laser cutting, help the customer to cut the required size |

|

Protection |

1. Inter paper available |

|

2. PVC protecting film available |

|

|

According to your request, each size can be selected for different application. Please contact us ! |

|

Surface Treatment

|

Surface |

Definition |

Application |

|

NO.1 |

The surface finished by heat treatment and pickling or processes corresponding there to after hot rolling. |

Chemical tank, pipe |

|

2B |

Those finished, after cold rolling, by heat treatment, pickling or other equivalent treatment and lastly by cold rolling to given appropriate luster. |

Medical equipment, Food industry, Construction material, Kitchen utensils. |

|

NO.3 |

Those finished by polishing with No.100 to No.120 abrasives specified in JIS R6001. |

Kitchen utensils, Building construction |

|

NO.4 |

Those finished by polishing with No.150 to No.180 abrasives specified in JIS R6001. |

Kitchen utensils, Building construction, Medical equipment. |

|

HL |

Those finished polishing so as to give continuous polishing streaks by using abrasive of suitable grain size |

Building Construction. |

|

BA (No.6) |

Those processed with bright heat treatment after cold rolling. |

Kitchen utensils, Electric equipment, Building construction. |

|

Mirror (No.8) |

Shinning like a mirror |

Building construction |

FAQ

Q1: How long does your delivery time take?

A: Generally, our delivery time is within 7-45 days, if there is a great demand or special circumstances, it may be delayed.

Q2: What certifications do your products have?

A: We have ISO 9001, SGS, EWC and other certifications.

Q3: What are the shipping ports?

A: You can choose other ports according to your needs.

Q4: Can you send samples?

A: Of course, we can send samples to all over the world, our samples are free, but customers need to bear the courier cost.

Q5: What product information do I need to provide?

A: You need to provide grade, width, thickness and the ton you need to buy.

Q6:What's your advantage?

A: Honest business with competitive price and professional service on export process.