Welded Pipes

Products Description

Welded pipes, also known as welded steel pipes, are made by rolling steel plates or strips into a tubular shape and then welding the joints. Along with seamless pipes, they are one of the two main categories of steel pipes. Their core features are simple production, low cost, and a wide variety of specifications.

I. Core Classification: Classification by Welding Process

Different welding processes determine the performance of welded pipes. There are three main types:

• Longitudinal Welded Pipe (ERW): After rolling the steel strip into a round or square cross-section, a seam is welded longitudinally (lengthwise) along the tube. This offers high production efficiency and low cost, making it suitable for low-pressure fluid transportation (such as water and gas) and structural support applications. Common specifications include small and medium diameters (typically ≤630mm).

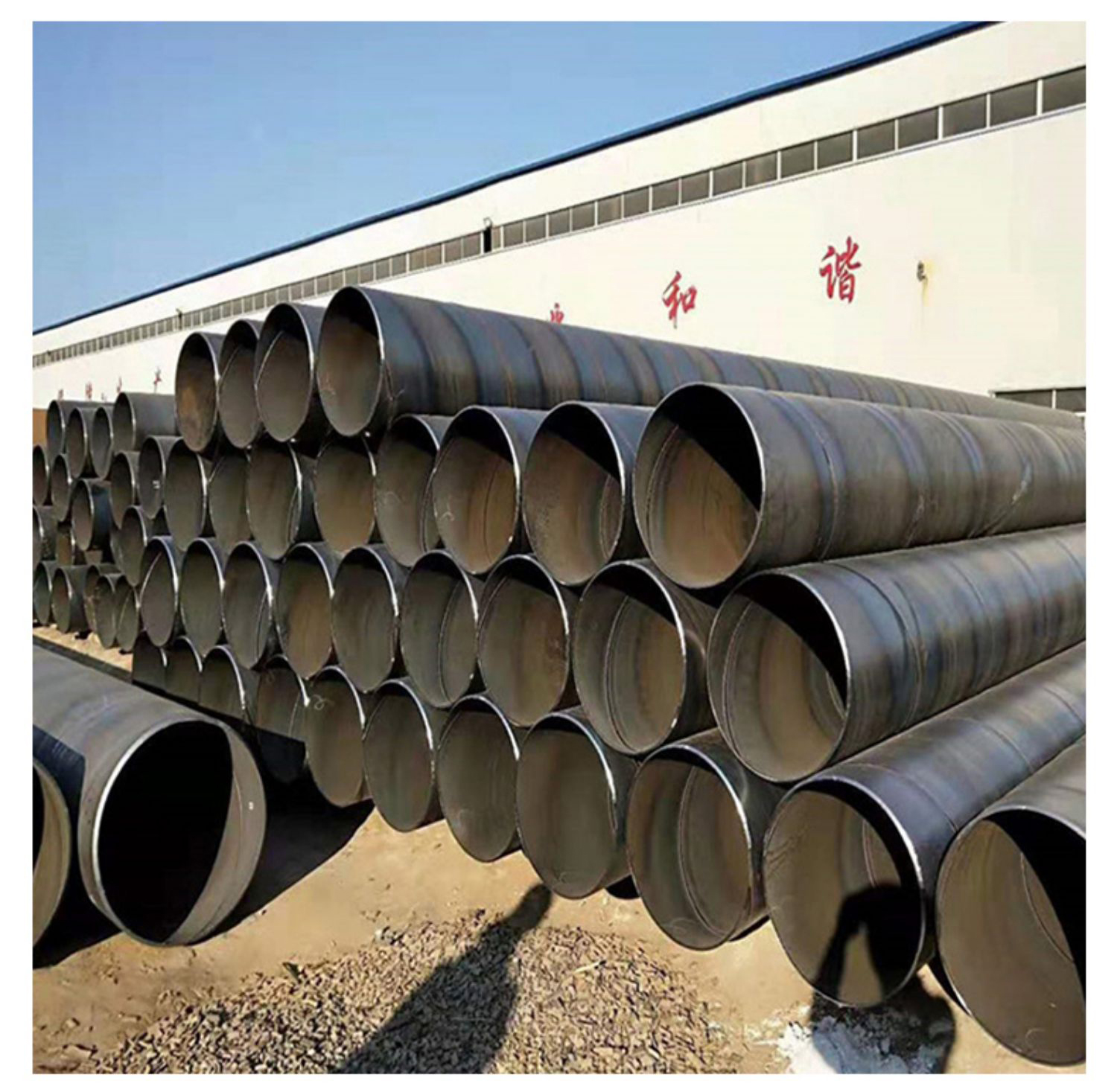

• Spiral Welded Pipe (SSAW): The steel strip is rolled in a helical direction and the seam is welded simultaneously, creating a spiral weld. The weld seam is more evenly stressed, offering superior tensile and bending resistance compared to straight seam welded pipe. This allows for the production of large-diameter pipes (up to 3,000mm in diameter) and is primarily used for high-pressure fluid transportation (such as oil and natural gas pipelines) and municipal drainage pipes.

• Stainless steel welded pipe: Made from stainless steel sheet/strip, welded using processes such as TIG (tungsten inert gas arc welding) and MIG (metal metal arc welding). It possesses the corrosion and high-temperature resistance of stainless steel and is suitable for applications requiring high quality materials, such as food processing, chemicals, and medical devices. It is commonly used in small and medium-diameter precision pipes.

II. Main Advantages

1. Low Cost and High Production: Compared to seamless pipe (which requires complex processes such as piercing and rolling), welded pipe offers high raw material utilization and a shorter production process. Costs are typically 20%-50% lower for the same specifications. Furthermore, it can be produced in batches and continuously to meet large-scale demand.

2. Flexible Specifications: Pipes with varying diameters (from a few millimeters to several meters), wall thicknesses, and cross-sections (round, square, and rectangular) can be produced on demand to meet the personalized needs of various applications, including construction and industry.

3. Easy Processing: Uniform material and stable welds facilitate subsequent cutting, drilling, bending, and other processing operations, ensuring convenient installation.

III. Main Application Areas

• Construction Industry: Used in water supply and drainage pipes, fire protection pipes, steel structure supports (such as scaffolding and curtain wall studs), door and window frames (rectangular welded pipes), etc.

• Industrial Sector: Used as low-pressure fluid transport pipes (water, compressed air, steam), equipment supporting pipes, workshop guardrails, etc.; large-diameter spiral welded pipes are used in long-distance oil and natural gas pipelines.

• Municipal Sector: Used in urban drainage pipes, gas pipeline networks (medium and low pressure), streetlight poles, traffic guardrails, etc.

• Daily Life: Small welded pipes (such as stainless steel pipes) are used in furniture brackets and kitchen ducts (such as range hood exhaust pipes).

Product Display